Control Rods

04/17/11 21:17 Filed in: All

Here’s a really bad Idea I don’t recommend - dipping the end plugs in primer. Ever anal about corrosion, I thought this would be a good idea. Even though the primer is very thin, it’s enough to make screwing in the rod-end bearings very difficult. Two turns in and one back out, almost like retapping the plugs. Once cleaned out they’re fine, but I am sure it was hard on the threads.

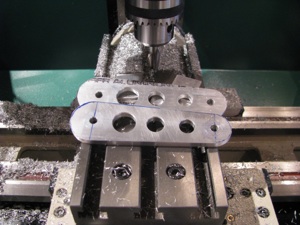

Another commercial for the Grizzly mill/drill. Bolt together the walking beams, bolt to the table at 3.5 degrees and mill away. Afterwards 20 seconds on the belt sander and done. Careful as the edges on milled parts are razor sharp.

All you machine shop nazis can rail on me for not using the proper collet on the mill, but changing is a pain and I took very small cuts. Of course I would switch over for more extensive jobs.

Parts starting to look finished - because they ARE finished. I know these will probably get dinged up during the continuous fitting/refitting, but the epoxy paint should be easy to touch up just before final assembly.

Cyclic assembly in ship with control rods preliminarily placed.

Front end of cyclic stick mounting.

Top view of mixer and rods.

Bottom view of mixer. Lots more washers than really needed so I don’t bite into nylon on any of the lock nuts.

Looking up at walking beams. Obviously they are not set to the proper angle yet.

This is a clearance issue with the stick full forward - actually it limits the stick from going full forward. You can see the fore-aft rod end touching the mixer bracket. I could grind a little off the mixer, but I am going to wait until things are closer to being in rig to worry about clearances. The main thing is that it all fits and there is little or no slop at all in the controls and they all move cleanly. Very cool to see this come together. There is almost no friction in the system and BJ seems to indicate that a little friction is a good thing, so I will go back and reinvestigate.

Of course now it all comes back apart.

With the preliminary placement I can see the extent of the travel on the slider. Now I can go back and clean up and paint the cyclic control tube.

I just have one support call to make to Eagle, which will be my first. The mixer U-shaped aluminum wings are held together with an AN4 bolt (which looks to be a change from the machined bolt in the videos). Two washers are supplied - presumably one for under the head of the bolt and one for under the castellated nut. Well, with a washer under the nut there is not enough clearance for the rod end to move. Without the washer the nut rides right on the aluminum of the “wing”. That doesn’t seem right. Hmmm...