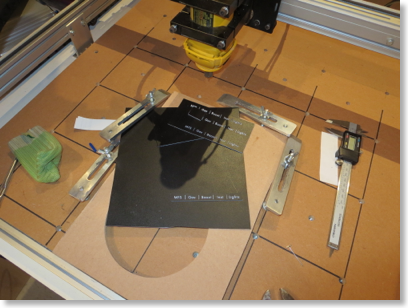

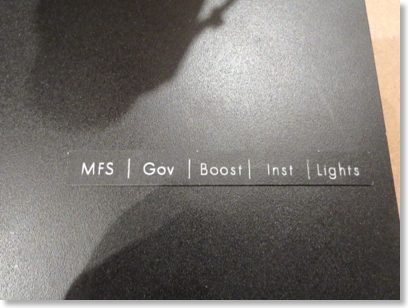

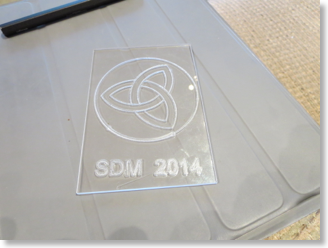

Switch Labels

Paint the white sheets with a couple of heavy-ish coats of satin black, then route the labels with a very fine point engraving bit. It took a couple of tries to get the right bit and the correct depth, but I am quite satisfied with the results.

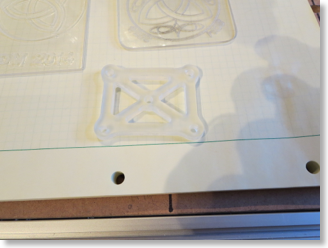

Since I have the detailed CAD for the panels I can easily come up with shapes that surround the entire switch area and are held in place by the switches. These are just test pieces, but I think I will go with this approach.

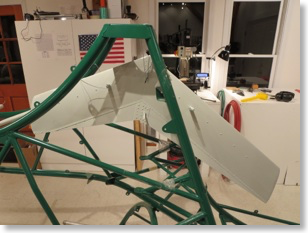

Cabin Interior painting

I had, at one point, considered lining the cabin interior with a fabric, but quickly dismissed it as weighty and labor intensive for limited gain in looks. To keep it simple and light, I lightly sanded it to remove the high-stranding fiberglass artifacts, then primed with the epoxy grey. I did not bother to fill the weave, or anything like that.

I wanted a finish that was light colored, but not reflective. The ideal solution was a stone finish spray paint. This is very similar to "spatter paint" that used to be popular as trunk paint for automobiles. I used Rustoleum "Simply Stone" granite finish. To me it looks nothing like granite, but for this application it looks pretty good.

The best part is that it really masks the open weave of the rough interior of the fiberglass. I highly recommend this stuff as simple and easy for this application.

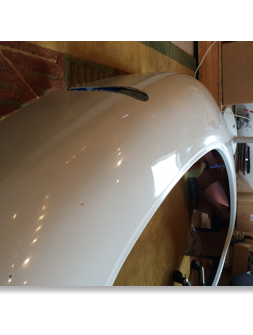

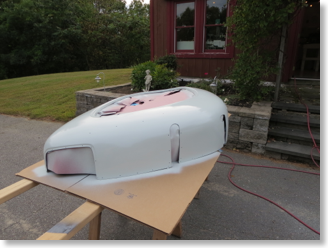

Cabin Exterior Painting

And thus begins the sad story of my cabin painting…

I have primed a bunch of stuff with only one real problem (see my SP priming entry), then I painted my fins and seat pan. The fins came out super-nice as did the seat pan. I was feeling like there were a bunch of pansies out there on the web, saying that painting was so hard and such an art form. If you read some folks descriptions it sounds like some god-like skills are needed. All of my things came out well enough that I was thinking there was not much to it. How wrong I was.

To make it easy for myself I had chosen a single-stage 2-part polyurethane paint for the cabin. The color is plain white, just to avoid any of the shading issues I read so much about.

When I painted the fins I was impressed with how nicely the urethane paint "flowed-out", and leveled itself, creating a glass smooth surface. So I jumped in to the cabin exterior using the skills and techniques I thought were developed at this point. The surfaces were primed, wet-sanded, masked and cleaned well. No problems. I used the same gun that I used for the fins.

The first coat went on fairly light. It was mid-morning and the temps were in the 70's and the humidity was relatively low outside. There wasn't as much "flow-out" on the first coat as I would have liked, but it was a light first coat. I expected the second coat to flow out better.

Between coats there must have been something in the gun that I had missed during the previous cleaning that broke off and clogged one of the output holes on the nozzle. No problem, I had another of the exact same gun in the shop. I would just swap the paint, set the new gun exactly as I had the first and carry on. This was my mistake. I made a couple of test swipes on my practice piece that is always outside when I am painting. It was a little grainy, but basically OK - or so I thought. I figured it would flow out in a minute or two.

Coupled with that was the fact that is was later in the day, the sun was now out brightly, and the humidity was even lower than before. After I laid down the next coat (on both cabin half exteriors) I noticed that it was not flowing out as I had experienced in the past. OK. Not good. I increased the flow a tad to try to increase the quantity So it would flow better and "fill-in" the grain. What I learned later was that I should have lowered the pressure as what I was experiencing was dry-spray, not a flow problem. Too much air was effectively drying the paint on the way out of the gun causing a graininess. Nuts. Even though my second gun looked exactly the same and was the same model, the second gun was a newer gun and was very different internally (I learned later).

Decision time; Stop or continue? In that few seconds I decided to lay down as much paint as I had and sand it smooth later. It was either that, or stop, let it dry, sand it all off, reprime, and re-paint. Other factors at work were the fact that this was probably one of the last days I was going to get with a good temperature and warm enough outdoors to paint.

So there I was - I had two cabin halves with the surface texture of table salt. It really looked bad. Time to start sanding. I hoped that I had laid down enough paint so that I would not thin it too much.

The next two weeks of evenings were spent with a spray bottle of water, sandpaper and dual-action orbital polisher. Start with 500 grit (yes 500 grit for real), wet sand, then work to 800, 1000, 1200, 1500, and then 2000. Follow that with a multiple passes of the polisher with an aggressive cutting compound. Wipe it all off, look at it with a bright light and repeat, starting with the coarse grit on up. Repeat. Repeat. Repeat.

I learned an awful lot about how paint behaves. First or all, it is very possible to work with paint. If it was just some light orange peel, I am confident that I could have smoothed it out nicely, with labor, of course, but not too bad. The problem with my situation was depth. If you think of the surface in profile as a jagged series of little sawtooth mountains, it is easy to sand off the "peaks". However, once you have created "plateaus", you have a much larger surface area, the ever growing plateaus, to sand to work in to the "valleys". Initial progress is fast and noticeable, then it slows way down.

Coupled with that is that once you get close to the bottom of the valleys, the paint is getting very, very thin. There are couple of spots that thinned through. I am pretty sure that someday I will repaint the cabin, but I am not looking forward to it.

After all that, I got it to the 10-foot stage, From 10 feet away it looks OK. Closer and you start to notice the problems. I thinned it too much in 4 places. The lip around the door was impossible to smooth. I am at the point where I could spend 3 or 4 times longer than I have and it might improve, but it will never be perfect. I have decided to call the effort, continue on, and if it really bothers me down the line I will repaint the bird when it is down some winter. This is a learning experience. My next helicopter will be perfect.

Final Pan and Pod Painting

This has been an incredibly busy summer. Unfortunately little of it has had to do with helicopter building; trips to Asia, Europe, India and Mexico for work, and buying a house in Virginia have consumed all of my time and energy.

When I have had time to allocate to the helicopter, I wanted to get some of the cabin pieces completed so that over the coming winter things could be mounted permanently.

I started the final painting with the seat pan. The finish selected is satin "Rat Rod Black". This is a flat black with a little bit of texture. The intention is that there be no unwanted reflections on the canopy.

After my priming problems I was a little wary, but the Rat Rod Black went on beautifully. I have found that textured paints are forgiving and relatively easy to apply.

I a quite satisfied with the results on the pan. The pod and panels were painted with the same stuff and they also came out nicely and as expected.

Doesn't that look nice? Very satisfying. The pod was a little more challenging because of the curves and undercuts, but it too came out well. Overall, I am very satisfied with these pieces.

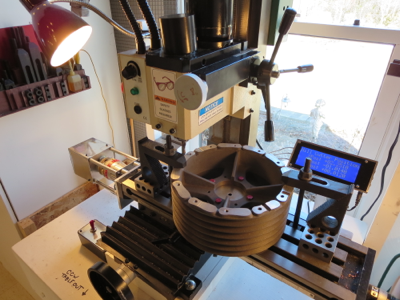

CNC Mill

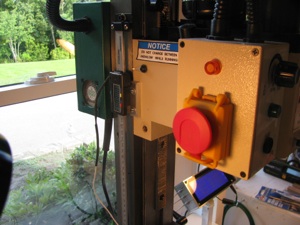

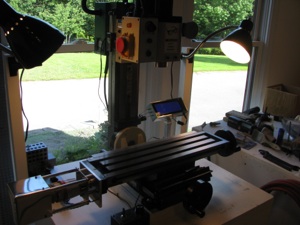

I did not want to spend a lifetime converting the machine, nor did I want to spend more than about $3500. This machine is substantial enough to cut up to maybe 1/2" aluminum. Parts and plans are readily available. I procured all the bits and pieces, and budgeted 3 weekends for the conversion. It took about three times that long as there is a lot of fiddling to get things dialed in perfectly.

The conversion deserves its own page, which can be found here: CNC_MILL.

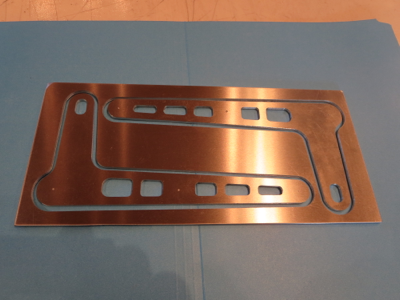

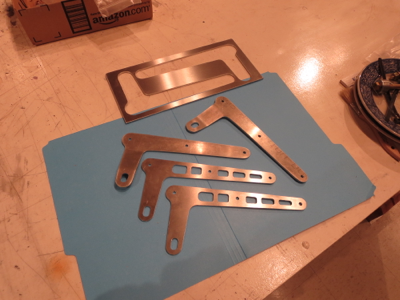

CNC Routed Parts

Fundamentally it lacks the stiffness for super-high accuracy or extremely clean cuts. It is belt driven and belts stretch. If you grab the carriage and wiggle it, you can move it back and forth maybe 10-15 mils. I have braced the metal frame, but fundamentally it is limited by that design compromise.

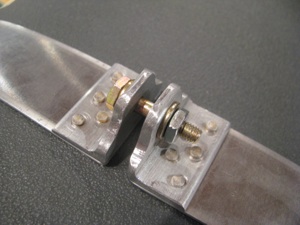

Still, for some sorts of things it is fine. I have just cut a new set of tail rotor control scissors. They are cut just as accurately as the hand cut ones I did earlier. The two pieces are nearly an exact match. The holes are drilled on the drill press as routing those holes would be insufficient accuracy. The routed slots for the steel bushings ARE at least as accurate as the hand cut ones.

I am satisfied with the results. Perhaps I will later try a new TR walking beam for pedal attach, The pieces I can fabricate are certainly straight, and light.

Old and new compared.

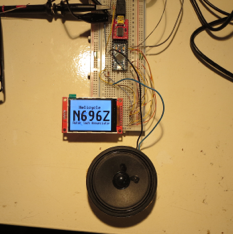

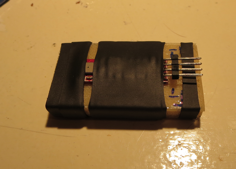

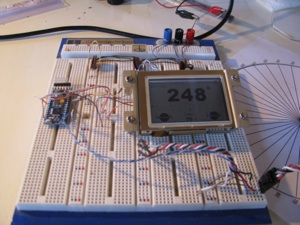

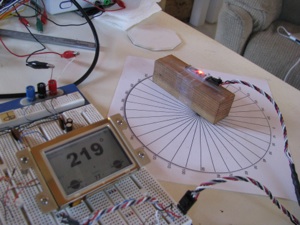

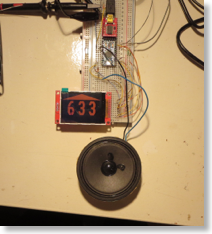

Rotor Tach

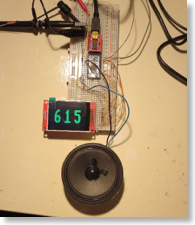

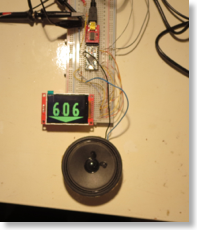

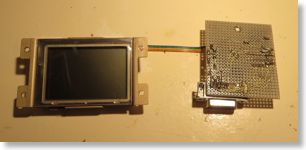

I built this little display item. It is based on a 2" display from eBay and an Arduino processor. There will need to be some conditioning to amplify the incoming signal and to make sure the analog tach is not affected. On the bench I use an audio tone generator to mimic the signal form the sensor.

If the rotor is in the range of 610 to 620 the RPM is displayed in green.

When in the range of 605 to 610 the RPM is yellow with a downward pointing arrow and a tone. Between 620 and 625 the RPM is also yellow with a higher pitched tone. Above 625 the reading is red with a red up arrow and a higher pulsing tone. Similarly below 605 it is also red with a red down arrow and a pulsing low pitch tone.

This is designed to be easy and very quick to read with an attention getting audio tone mixing in to the headset feed. I plan on mounting it on the top of the pod as it is critical to interpret this quickly during autorotations. In the final incarnation this will be packaged well and be brighter. The display shown here is a tired old one I have beaten and abused and use for development where I may actually damage it.

Jack Table

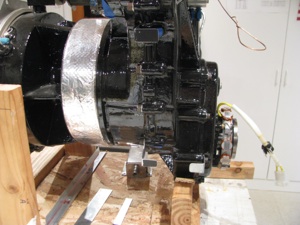

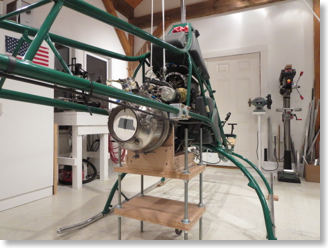

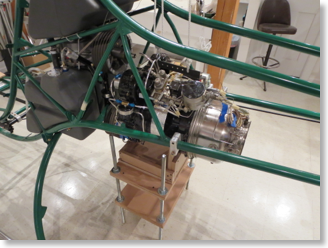

The engine went on the floor and I modified the cradle so I could just hoist it straight up and out.

Then I tried lifting the engine with my pulley system. Two problems; 1) The rope was quite stretchy. I can't imagine trying to position the engine precisely with this system., and 2) Seeing the engine dangling from a few thin strands was too nerve-wracking. That's 10-15K worth of turbine swinging on some home-depot rope.

It probably would have been fine, but between the swinging and the tough precision thing I knew I wanted to do something different.

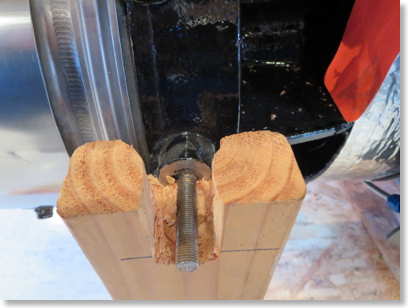

So I went to Home Depot and picked up some 3/4" threaded rod,washers, and nuts. 3/4" is certainly way overkill for the engine's weight, it's more for the stiffness so I don't need much more structure to keep the torsion and twist under control. I had a ton of MDF pieces left over from my CNC router project.

I made a new cradle for the turbine and added another thick interim layer to keep the whole thing stiff.

The idea is to transfer the turbine over to this jacking table and use the nuts to incrementally raise the engine up. Should be very safe and allow for very precise positioning.

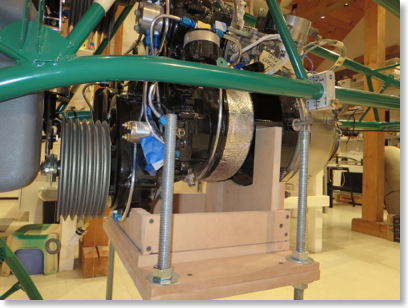

So here is the turbine in position after incrementally jacking it into position. It's very stable and certainly not going anywhere, so I can fiddle with alignment all I care to before locking it down permanently.

HERE is the whole process of building the table and jacking the turbine.

Of course after taking the photos and staring at it I realize I forgot to put the belts on so I will have to lower it a couple of inches and slide the belts on.

Blades are Back

I went to pick up my blades from Conway Freight today. They are back and they have been machined. All I have done is crack the crate and have a peek.

There are no more excuses standing in my way of completion now.

Shop Day

The camera has the ability to monitor for motion, and then push images to an FTP server every second when there is motion detected. I then use an application called "Time Lapse Assembler" to string them into a movie.

Here is a day in the shop. The only frames logged are when I am in view and there is enough motion to trigger the camera, so it is not a full day, but several hours worth. Still, it's pretty big if you chose to download it.

This will get more interesting when there is more action on the airframe. Most of this is engine prep work. With a low-resolution video camera like this it makes for a pretty boring video. I will remedy that soon enough.

Tasks accomplished on camera:

- Safety wiring some engine fittings

- Doing the last bit of engine wiring.

- Torque sealing a bunch of bolts (my way of indicating completion)

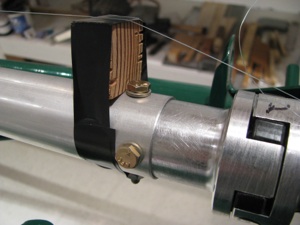

- Fabricating, painting and installing a bracket for the throttle return spring

- Checking the clutch travel and figuring out how it mounts in the ship again.

- Replacing the skid bolts with AN HW of the proper length (the kit-supplied Grade 8 bolts ones are too short).

- Prepping the rubber clutch mount

Engine Prep

You have to fabricate a little bracket to attach the throttle return spring. I have seen Helicycles that just use a piece of angle here. Well, I shaped and sculpted that stupid little piece way more than necessary.

Here it is painted (well, primed, anyway) and mounted on the ship. Kind of a nothing of a task, but probably way easier on the bench than in the ship.

To prep the rubber clutch mount I coated it with Vaseline to loosen the mold-release skin, then rubbed it off the rubber, painted the metal plate (with diluted black nail polish for quick drying), then coated and soaked the rubber in Armor-All to keep the rubber "supple", and lastly coated the bore of the bushing with Corrosion-X. Again, probably overkill since I am sure many just bolt the darn thing in the ship without bothering with any of that.

If you take a half-full bottle of nail polish, top it off with acetone, and shake it up really well, you get a quick-n-dirty lacquer paint. It dries hard as soon as the acetone flashes off. It is not rugged, nor pretty, but for a quick corrosion inhibitor, it saves a ton of time versus real painting.

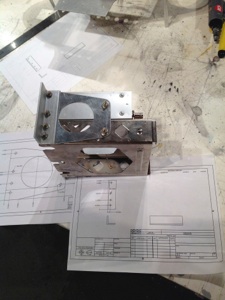

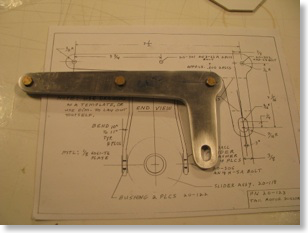

Engine Hoist Bracket

That's just some hardware store GR8 bolts and angle iron from Home Depot. I had forgotten just how nice steel is to work with. Drilled a bunch of holes since I do not know where the CG of the engine is. This way I can just hook on the closest balance point. If this were a permanent thing I would have used more and better mounting points, but it is a single-use, single-function item.

Oil Tank Buff

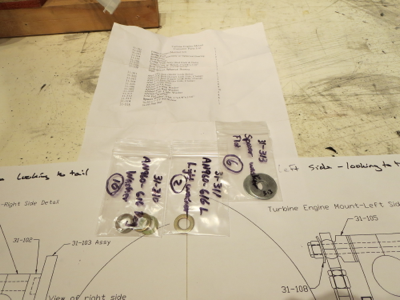

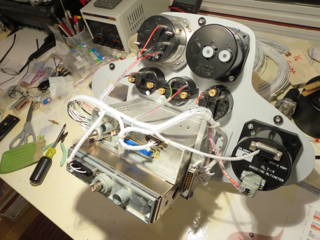

Engine Mount Prep

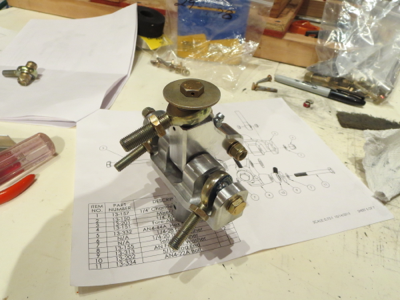

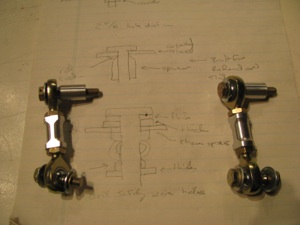

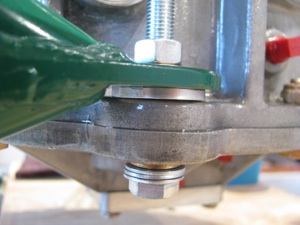

Here are the assemblies for left and right fit together.

I have a question for Blake as to which way to install the bolts for the inner slider plate on the left side mount; nuts in or nuts out.

There are a few spare parts, all washers. I am assuming those are for proper spacing once the unit is installed in the ship.

I mounted a couple of heavy steel angles and pulleys to a large beam in my shop for winching the engine up into position.

Next up is to check the gear (since major weight will be on it now), and complete the wiring of the engine, then the mounting starts.

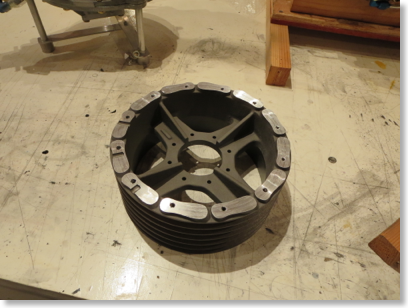

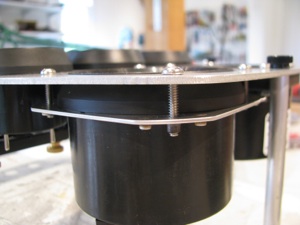

Pulley Balancing

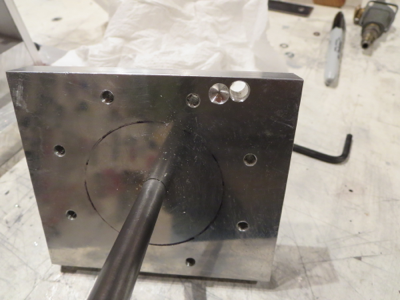

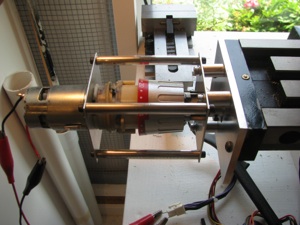

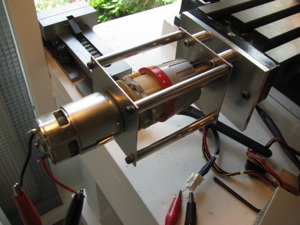

So I built a balancing jig. It's sized for the main transmission pulley and pretty basic. Some heavy stock for the sides and base and two sections of stainless steel ruler (Harbor Freight $1 items) for the "knife edges" sanded and polished on the edges.

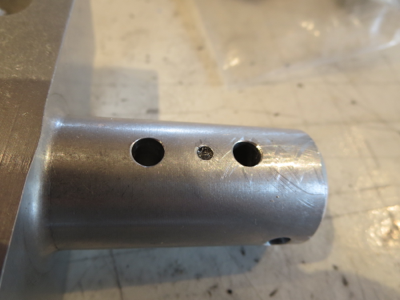

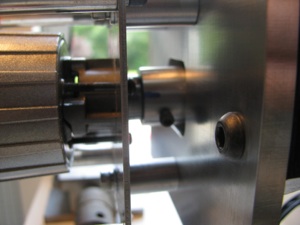

The carrier is an "almost" square block. I measured and drilled the bolt holes for the pulley flat face as precisely as I could (again, the mill with DROs is a godsend). All holes are +/- 0.002" of their ideal position. The center spindle is a piece of 4130 steel tubing. I drilled the center hole slightly undersized and sanded up to a super snug press fit. Once pressed in the tubes were sanded and polished.

Next, the carrier assembly itself has to be balanced as perfectly as possible and the jig leveled. The through hole and the partially drilled hole achieved that balance. There were already some partially drilled holes on the other side of this block, and the drilling ops are not perfect, no matter how carefulIy it was machined. This is a very important step. When the carrier spindle is balanced you can level the jig with shims to be perfectly level. Even the tiniest of differences causes the balanced item to roll off one side or the other. It's pretty impressive how delicate/accurate this thing is.

Only THEN can you start balancing the pulley. Bolt it together, see which side is down, mark it, redo the measurement with the carrier at 4 90 degree points, then draw lines across the face of the pulley. The center intersection point is the center of gravity. Since the carrier is not perfectly centering, you must do four measurements at the cardinal points and then draw the centroid. Only THEN remove material on the heavy side - a little at a time - then repeat.

It took several hours, but I am quite satisfied that the balance is WAY better than anything achieved taking the pulley right out of the box, especially if you bolted those hand-cut cooling fins on. I am pretty sure it is now within a gram or two of perfect balance.

Bolted, torqued, and torque sealed in the ship for the last time! Another "final assembly" thing down. On to the engine!

Last SP Priming

I also spent a whole lot more time tweaking the gun for a good spray pattern and quantity. This is kind of a matter of feel as much as anything else.

The interior of the cabin will be painted with a Rustoleum "Simply Stone" textured paint. It's kind of like spatter paint from old car trunks. The seat pan top and instrument pod will be satin black for low reflections.

More SP Priming

DISASTER. Right when I was thinking this painting stuff wasn't too hard, this thing turned into a runny, saggy, ugly mess.

Yuck! You can see the sags, runs, and droops.

This is the cut panel blank which I primed as well. Those aren't really fisheyes. They are more dimples.

Very rough texture when dry.

Conclusion: Weather, weather, weather. Whereas when I primed the rear of the pan, the day was sunny and dry, the day I did the top side was cloudy and overcast and the humidity was relatively high. It was supposed to rain that afternoon and I wanted to get the primer on before it turned wet. Because of the moisture in the air and the lack of sun I think two things happened. 1) When I did my final wipedown with IPA, it never evaporated all the way. I think that is why the panel has the dimples. There was still residual IPA in the pores of the aluminum. 2) Because of the moisture and lack of sun, the primer did not dry or flash as quickly. The longer to stayed on wet, the more it sagged and ran.

This epoxy primer is tough stuff, so this will be laborious to sand off and start again, but that is the price to pay for getting too cocky about painting. At least it was the only primer. My lesson is learned and I will redouble my attention to conditions.

Lesson learned.

Seat Pan Rear Priming

I broke out my Eastwood 2-part epoxy primer for a quick couple of coats to seal the rear of the pan. This stuff flows nicely and surprisingly almost exactly matches the color of the plastic used on the fuel tanks.

I am not too concerned about the finish on the backside of the pan. This is just a sealer, for the most part.

Reno 2014

I attended the National Air Races in Reno this year (2014). In the display area were two different Helicycles. This was awesome as I have been to a number of Sun-n-Fun and Oshkosh events, and have seen exactly ONE Helicycle at Sun-n-Fun in 2013 only. There were two on display at Reno this year, an official corporate presence, and information on the Helicycle that is being used as a drone. A wonderful showing.

The first machine was Blake’s personal machine from Eagle R&D. This is a basic workmanlike machine that is actually a collection of parts from a number of builds. Here is a slide presentation of Blake’s Factory machine. They may seem like a random collection of photos. They are of whatever was interesting to me at the time.

The second was James Kent’s machine. This thing is a work of art. James has added a number of very advanced enhancements and is finished to a supreme degree. Polished surfaces, chrome plating, and superior craftsmanship really makes an outstanding impression. I didn’t get as many photos of Jame’s machine as I have a whole bunch from Reno a coupe of years ago. Here are a few detail shots of some of the nice touches.

James’ machine was absolutely swamped at the show every time I walked by.

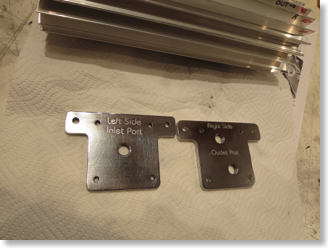

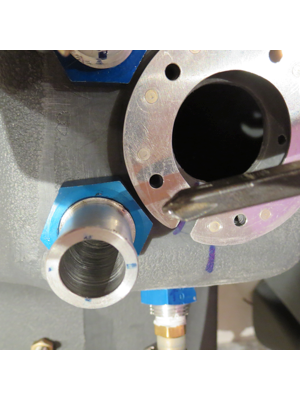

Oil Cooler Endcaps

Here are the end caps to the Hap Miller supplied oil cooler. This labeling is not strictly necessary, but a start.

I am definitely learning what works and how to work the machine. I engraved too deeply initially and snapped the first engraving bit and had to restart. That's why the "L" and the "e" in "Left" are a little smeary; two passes at a one-step offset that probably happened when I changed the bit.

That's just a quick "shop polish". A camera angle that highlights the engraving also highlights the unpolished scratches in the aluminum. I am thinking I will just leave the oil cooler extrusion "natural clear anodized" and the end caps polished (more than this, though).

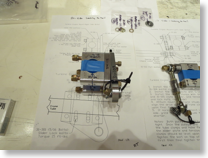

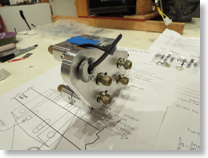

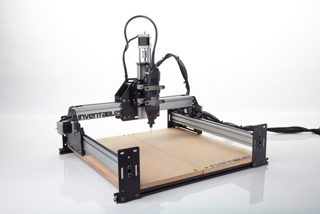

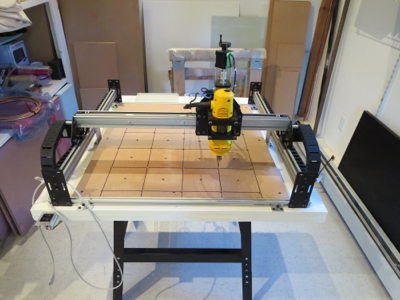

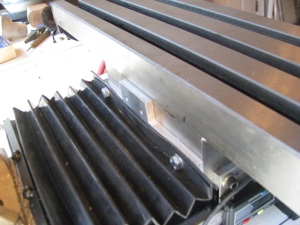

Shapeoko 2 CNC Router

For my birthday I got a Shapeoko CNC router. Shown is the basic stock configuration. I only purchased the mechanical kit (no motors or electronics). The first thing to do was assemble it as shown and then evaluate where it was strong and weak prior to modifications.

My goal with the machine is to be able to fabricate complex brackets out of (up to ) 1/4" Al plate. I thought about a real CNC mill, but was not willing to invest the time or cash at this point for a big machine. Turns out that was probably a good idea. This is a neat machine, but it may fall short of my goal. Still, it is a great way to learn CNC without a massive investment and to figure out a tool flow and develop experience that would be far more expensive to do with a bigger machine. I will ultimately end up probably with a CNC version of the Grizzly G0704, but that is a longer term thing.

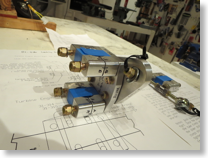

Here is my own modified end product:

Modifications include:

1) Longer X and Y travel by 50% (up to 750mm from 500mm) doubling work surface area

2) Stiffening Y travel with mid-span brackets

3) Stiffening X by bracing dual extrusions together. Reduces torsional twist.

4) NEMA 24 motor upgrades on X and Y axes

6) Dewalt DW660 router for cutting. This thing is a beast. Very, very loud, though.

The table is a Harbor Freight $29 tool table. I buy less and less stuff from HF because of their marginal quality, but sometime they have just the thing. The base is layered MDF up to 1.75" think. The sheets are screwed and glued, but prior to that I shimmed them the best I could for flatness. The wasteboard is 0.75" thick.

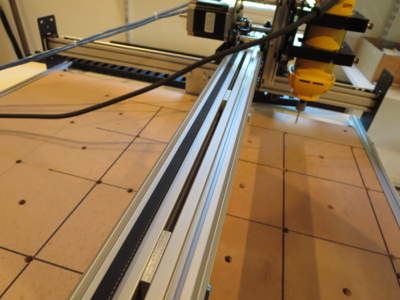

The Y-axis motors are NEMA 24 upgrades. a little shimming and careful attention to build order in order to fit it all together. Some quick lathed mounts for the drag chain.

Whipped up a couple of braces for Y-axis support. Simple angle and plate machined up on my mill. Riveted with aircraft project leftovers. Nice to have the tools and materials at hand. The longer Y-Axis needs support in the middle and this also keeps the fore and aft direction from flexing.

Whipped up a couple of braces for Y-axis support. Simple angle and plate machined up on my mill. Riveted with aircraft project leftovers. Nice to have the tools and materials at hand. The longer Y-Axis needs support in the middle and this also keeps the fore and aft direction from flexing.  The stock configuration only has the pair of extrusions only attached at the ends. To keep the extrusions from flexing relative to each other, I first built up the carriage, fitted it, and measured and fabricated proper thickness shims to affix them together. This really stiffened up the carriage in the vertical dimension.

The stock configuration only has the pair of extrusions only attached at the ends. To keep the extrusions from flexing relative to each other, I first built up the carriage, fitted it, and measured and fabricated proper thickness shims to affix them together. This really stiffened up the carriage in the vertical dimension.It is important to build it up before measuring for the shims as the width can't be determined accurately until the thing is fit together to find the "natural" width of the carriage rollers.

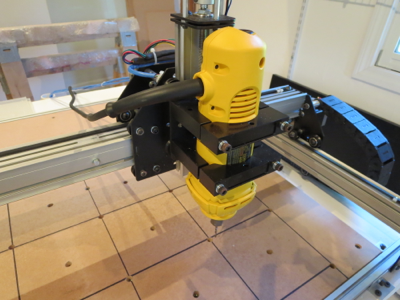

The DW660 router is much heavier than the stock spindle and needs good bracing. The wires from the X-axis and router will be dressed better when I get a smaller drag chain. Works for now.

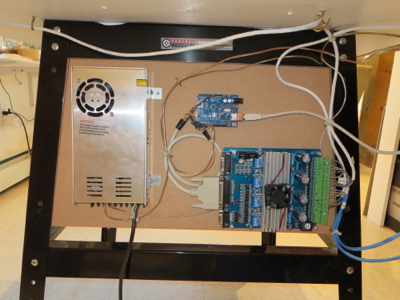

Electronics bolted to MDF plate in the back of the machine. Protected by the table top, so I didn't feel the need to make a full case.

The motors and controller were purchased off ebay for about $200 from wantaimotor.com. Wow. Lots of capability for short money. It all worked, but was not at ALL documented and the limited docs that were provided were WRONG. A lot of web searching and reverse engineering needed to figure out pinouts, voltage levels, and controls. The controller is an Arduio UNO ($10 on ebay) running GRBL. Doesn't get much cheaper for CNC control.

Made some hold-down brackets on the mill. The washboard has an array of T-Nuts installed flush from the bottom. Screw the threaded rod from the top into the wastboard, slip over the hold-down, adjust the carriage bolts for the right angle, and then spin the wing nuts to tighten. Simple and effective.

Made some hold-down brackets on the mill. The washboard has an array of T-Nuts installed flush from the bottom. Screw the threaded rod from the top into the wastboard, slip over the hold-down, adjust the carriage bolts for the right angle, and then spin the wing nuts to tighten. Simple and effective.My tool flow is:

Spaceclaim (running under Windows VM on my MAC) - 3D and 2D modeling of parts and brackets. Export is DXF (2D) or STL (3D)

or

Adobe Illustrator (running OS-X on MAC ) for art drawings and 2-D text for engraving. Export is DXF

CAMBAM (running on Windows-VM on MAC)for tool path generation. http://www.cambam.info

Universal G-Code sender (running OS-X on MAC) for controlling the machine (free)

So all-in I had to buy CAMBAM for about $180. The rest was free or something I had already.

Here are some early examples in some plexi scraps I had lying around. Obviously I have to work on tooling and feeds for better results. Cutting plexi is weird in that you have to be careful. If you cut too fast it "fragments" at the cutter. Too slowly and the plexi melts and build up on the cutter, affecting the accuracy of the line.

Conclusions:

For engraving this will be great. For milling soft stuff it's probably fine - haven't done much there yet. For aluminum it is weak. It is just not stiff or strong enough, even with my modifications, to accurately cut thicker plate. I will experiment with speeds and tooling to see if something acceptable can be determined.

The machine works great for what it is. I can see perhaps cutting outlines and lightening hold in brackets, then moving the piece to the mill for accurate cutting of holes. It is very satisfying to see it run repeatably and position accurately; hypnotic almost. I have learned a lot and when I do get to the construction of a man-sized mill it will go much more smoothly. I have purchased a 2W laser from ebay to try my hand at laser etching. That'll add a whole new level of danger to the shop.

My total investment is about $700 and a month and a half of weekend spare time. I think of it as a self-taught course in CNC machining. From that perspective it seems pretty cost effective. It's now just another tool in the shop. Like the Mill - it was a project that once done will become a very useful tool. Time to get back to the Helicycle.

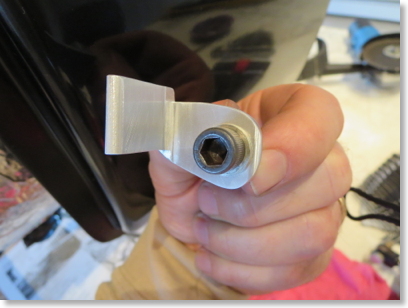

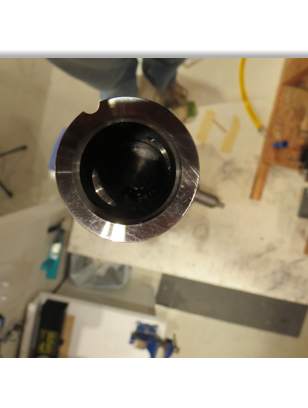

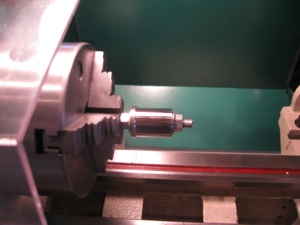

Main Shaft Plug

Well ahead of the transmission installation video in the rotor head video, BJ mentions how the main shaft should be plugged to keep out moisture. First up was to slather a goodly amount of Corrosion-X in the shaft after a few acetone swipes. Then I lathed up an ABS plug that was snug, but not even really "tap tight". Once parted the plug is only about an inch long.

The plug was coated with 5-minute epoxy and slid down inside the tube. I measured the steel main drive plug that slides inside the shaft, then I pushed the moisture plug down plenty far enough to clear the plug when it is installed. While the epoxy was setting up I wiped and cleansed the inside of the tube above the plug with acetone to remove any trace of the epoxy so the drive plug will not be fouled when it is inserted.

The edges of the hole for the drive pin are sharp, sharp, sharp, and I cut the hell out of my finger while swabbing out epoxy. Nice mixture of acetone and epoxy now coursing through my bloodstream. About every two weeks I will cut a finger, grind myself or otherwise accumulate minor scar tissue on this project.

Lower Tank Closeup

I dried out the lower tanks and closed up the access hatches. Of course I discovered that there was an interference between the retention ring then the inner part of the nipple fitting inside the tank on the left side where things are pretty tight. Fishing the ring in the tank without dropping it is bad enough, but then fishing it back out is a double pain.

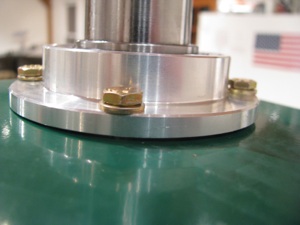

Once sealed, the tanks were pressurized with an extremely sophisticated, NASA inspired pneumatic pressure source. Then all the joints and interfaces were brushed with soapy water to check for bubbles. No bubbles.

With this last set of tasks on the lower tanks, they are ready to install. They can't be final installed, though, until the main transmission is installed. That is now the focus. It has already been fitted once and aligned, so all that's left is to reinstall the plumbing and some final surface prep with Evershield.

Surprisingly those balloons were pretty good. They stayed inflated for 6 days with only the slightest shrinkage. Usually party balloons self-deflate after a day or two.

Rebalancing the Pulley

The locations that needed milling were on the side opposite the holes that had been drilled. This kind of makes sense if the holes were drilled to compensate for differences in the mass of the bosses that were milled off.

Lower Tank Final Prep

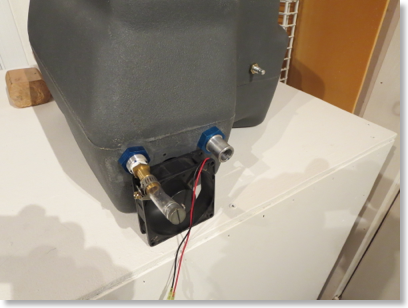

I blew all the crap out of the lower tanks and gave them a good rinse. I did not want to do the final rinse with gasoline as BJ suggests since all my work is inside my shop and it would get stunk up. That left the problem of drying them out after a rinse. Turns out that a little muffin fan blowing in the large hole and venting out through the upper hose nipple was enough airflow that after a couple of hours they were bone dry inside. Excellent. Next up a pressure test.

Transmission Final Prep

Now I have to dig out my references on how to re-install the plumbing.

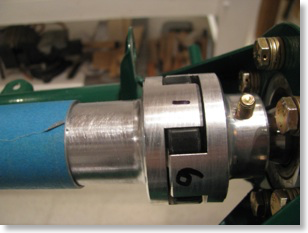

Since I am not planning on installing the fiberglass fan blades the bosses cast onto the pulley are just dead weight, so I chucked up the main pulley in my lathe and shaved them down. Any extra room in the pulley bay will be welcome I am sure. I left a little meat on the pads from the bosses to give me something to mill off in case there is some balancing to be done. You can see the remains of a couple of leftover holes that must have been drilled for balancing purposes back at the factory. I will admit that I did not notice those balancing holes until I started cutting and now will have to rig some sort of jig to allow for redoing the balance.

This is the largest thing I have ever worked with in my lathe and it was clearly operating at capacity.

Top Tank Final Mount

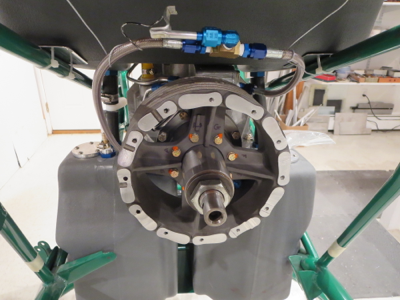

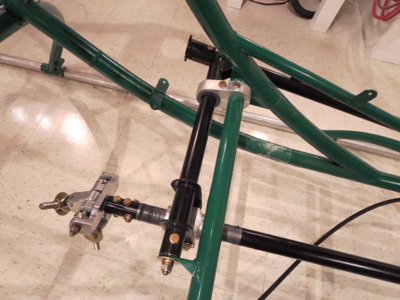

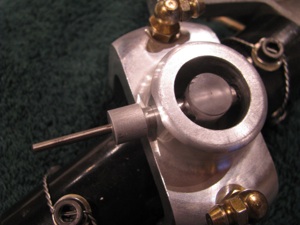

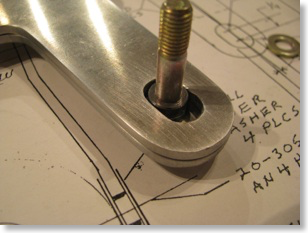

Clutch Final Assembled

I used the Hap Miller compression disk instead of the stock rubber biscuit. Looks nicer and should be more stable. The bolts holding the angle plates are only bolted through the tubes, so the bolts can't really be torqued to spec (60 in-lb) without deforming the tubes, so torque was lowered a bit. All bolts were Loctited and all sliding surfaces were greased prior to final assembly.

Controls Installed

Everything is torqued and safety wired. I put a dot of torque seal on the nuts after final installation. Since all the pieces had been pre-fit, it was very straightforward. The only annoyance was that one of the Grade8 bolts I had purchased pre-drilled really wasn't drilled all the way through. It demonstrated that the Loctite sets up very quickly. The portion in the threads was already gummy after only an hour or so after installation.

The control stick has almost no resistance fore and aft due to the bearings in the stick, but a slight amount in the left right since it is turning the cyclic shaft in the slider. It;s all greased well, and there is no breakout force, per se. We'll see how it all feels when the rest of the control arms and fittings are installed.

Mixer Assembled

Clutch Pre-Assembly

Next up is drilling the side plates to the clutch lever arm. I made use of my jig plates (from the cyclic tube mixer mount operation) to get a perfect alignment between the bolts and the holes for the plates.

Jig plates repurposed and alignment exact. It pays to make sure that mill is perfectly level and mill head is trammed. Then everything can be referenced to 0.0 degrees or 90.0 degrees.

It seems like a pain to make little jig thingies for a single operation, but I usually can find a secondary purpose for them which make the time spent much more worthwhile.

Complete clutch assembly pre-fitted (except rubber parts and bearing). Now I just have to tidy up the steel parts (they picked up some scale having sat for so long), prime, and paint. With the precision of the mill, and no broken drill bits, the pieces just fall together, snug and true. The clutch is a very simple assembly project.

Mixer Refit

The original mixer (partially disassembled) looks fairly primitive next to the nicely CNC machined parts of the new one. I was never a huge fan of the single bolt in the center holding the "wings" together.

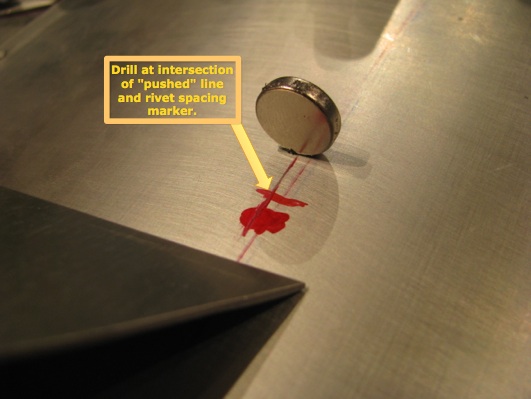

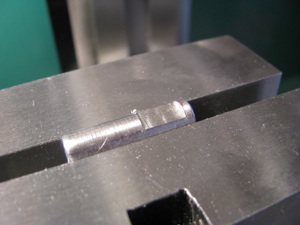

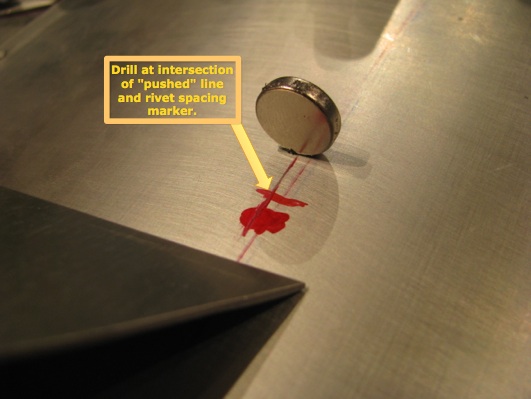

Start by drilling the hole for the safety wire on the fore/aft arm. On the collective slider I did them "free-hand". On this piece and with the mill and a couple of holding blocks this is achieved in very short order and with less hand wringing. Center punch the start location. Use a center drill to provide a "divot" so the real drill doesn't wander and away we go.

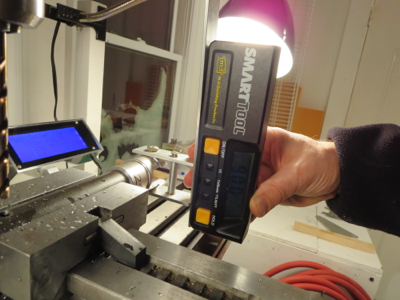

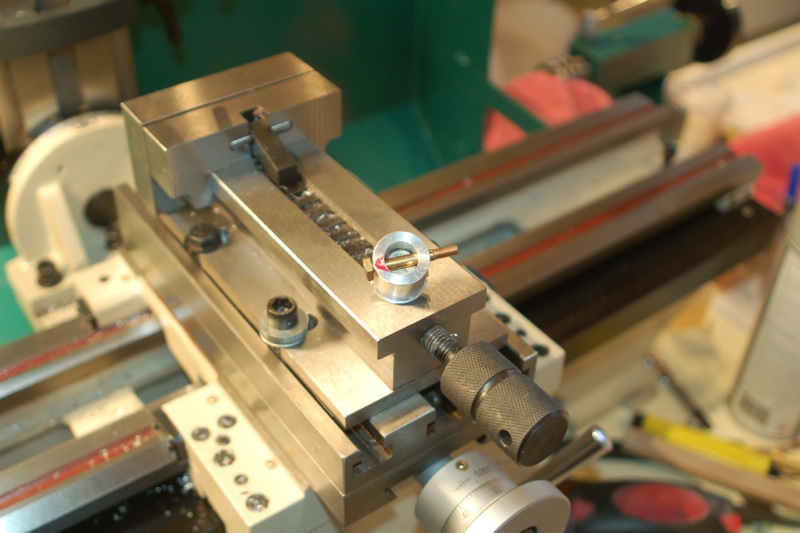

To precisely align the mixer with the control stick I made a little jig. Those two aluminum plates were machined in a stack, so they exactly match. The holes were drilled and the top edge machined to form a precise reference edge/plane. Both plates are exactly the same dimensionally. Then I made a little spacer on the lathe the exact same width as the cyclic bolt tube. Bolt 'em together and place a bar across the reference edges. My digital level was then used to get the angle between the reference and the bottom of the mixer block to exactly 0.0degrees.

Of course right when I was feeling smug and competent, BAM. The drill bit snapped off on the first hole. Crap! About half an inch into the hole. Of course you can't drill into a drill bit, so instead of boogering things up I stopped and stared at it for a while.

First I tried digging the broken bit out with a pick and needle nose pliers - no joy. Then I milled the hole slightly and the broken end of the drill bit. At least at that point I could remove the mixer block.

I tried using the "old" rearmost vertical hole first and matching the hole (you can see the hole on the left) Though very, very close, the hole on the other side of the tube was slightly oblong (by about 10 mils). I went ahead and drilled the horizontal cross bolt.

Why the bit snapped I don't know. It was only eating into aluminum at that point. It was well oiled, and I was backing it out regularly to clear chips. I was attempting to use a #30 bit as the pilot and that is probably a little wimpy for a hole this deep. Here you can see the remains of the broken bit with about 0.5" missing (in the mixer block).

Even though it probably would have been OK, I carefully measured and determined that there was room for a third hole in between the others. You can see the middle drill bit here showing that hole. Pretty busy. The forward most cross hole is perfect, nice and snug. The rearmost one is the one I tried to match - sloppy on the far side. The middle is my auxiliary hole - also nice and snug. OK. Good. Crisis averted.

The mixer block removed from the cyclic control tube showing the three holes. Since it is solid aluminum I have no concerns over strength. The broken bit will ride along with me forever stuck in the aborted hole.

The rest of the mixer assembly is a non-event, just assembly with a little sanding to make everything slide together smoothly. Off to paint.

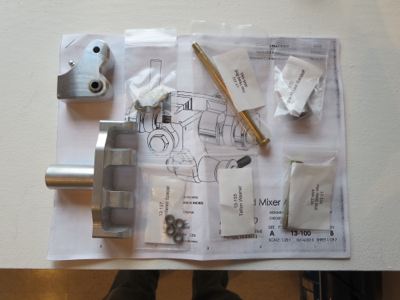

Received New Mixer

Final Pedal Mounting

I went to FINAL mount the TR pedals as it is time to start placing some things on the ship for the LAST time now. When I went to snug the bolts up it all bound up and was very stiff. Not good. Controls are supposed to have some damping, but should be butter smooth with no stiction.

After staring at it for a few minutes it became apparent that when the AL bushings are snugged up, they get pulled against the welded steel tabs that mount them to the frame and those tabs are not perfectly square with the mate on the other side of the frame for the opposing bushing. That "tilts" the bushings and cause them to bind in the tube.

No problem. I have all these machine tools - time to put them to use. I lathed down and threaded an aluminum rod that was the appropriate length to thread into the bushing to "point" to where the alignment was on the opposite side.

With those very evident visual cues it was very easy to tweak the mounting tabs (it didn't take much) to bring everything into nearly perfect alignment.

Amazing how such a small change resulted in such a large difference in the feel and operation of the pedals. Greased up, snugged up, Safety wired. The first permanent moving part. Lots to follow in a short period. Nice.

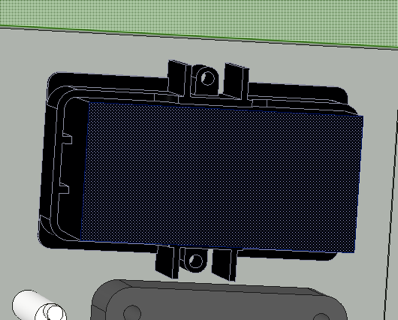

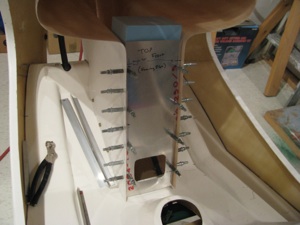

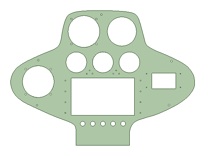

Lower Panel Crafted

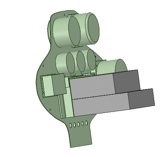

Start with a quick CAD model of the instruments and panel. If anyone is interested in the solid models I used, just email me and I will post them.

I almost neglected to model the rear retaining ring around the Red Lion tach. Can;t skip that because it's quite a large thing. Once everything is modeled, it is easy tp check for interferences and tweak the position if required.

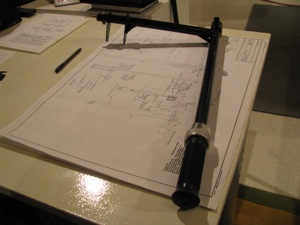

Once the modeling is complete, add some dimensions and make a detailed drawing as I did HERE. This is the primary reference sheet when machining the holes in the sheet.

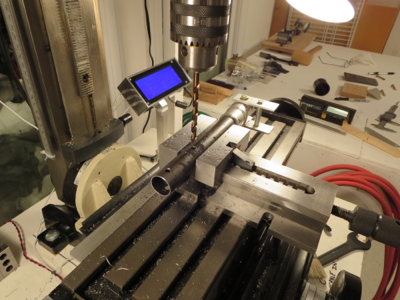

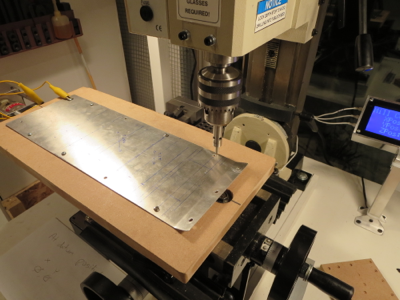

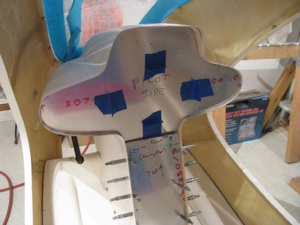

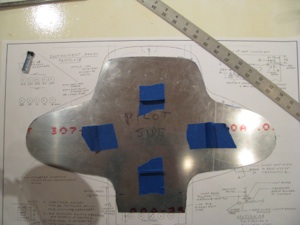

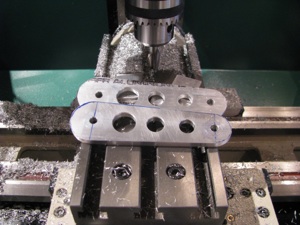

The blank queued up on the mill. Prior to this the blank had been cut and then fit into the instrument pod lower. The side mounting screws were drilled in assembly with the support strips in the pod. Perfect alignment prior to this drilling/milling operation.

On the mill I bolted a piece of MDF to the table (mounting bolt recessed, of course). Then the blank was trammed to the mill so the edge was in perfect parallel alignment with the quill. Very small wood screws are then screwed through the mounting holes to solidly affix is to the plate. The front mount hole and edge are the home reference.

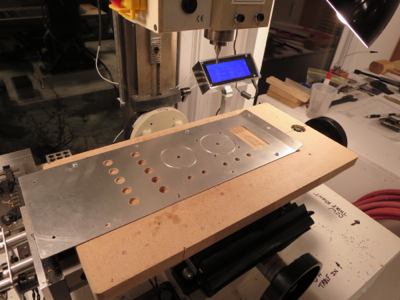

The Lower Panel machined. I love that little mill. Though time consuming, the accuracy is impressive. Digital readouts on each axis make repeatability and accurate positioning very easy. I used my hole jig for the circles, and milled out the tach square with a 3/8" end mill. The corners were finished with an 1.8" end mill. If needed I will file them down.

All the stuff preliminarily fitted. My holes for the indicator lights were a bit small and the fuel monitor hole needs some trimming, but by and large the fit is pretty good. All the holes are alignment nicely and very square.

DVD Index

I finally got around to indexing the contents of the DVDs. At this point I need to find certain things quickly. All the DVDs have been loaded onto my iPad so I can reference them quickly in the shop. Also shown is the order in which the items should be completed for final assembly.

| DVD Contents | ||||

| DVD | Group | Sequence | Subject | SDM Order |

| 1 | 1,2 | 1 | Full and Half Door Construction | |

| 1 | 1,2 | 2 | General Construction and Fitting Landing Gear | 1 |

| 1 | 1,2 | 3 | Cabin and Trim Fins- Floor Pan, Pod, Cabin, Windscreen, chin window | 2 |

| 1 | 1,2 | 4 | Cabin and Trim Fins continued - Trim fins and mounting. | 3 |

| 2 | 3 | 1 | Fuel System | 4 |

| 2 | 3 | 2 | Direction Controls, Cyclic Controls | 5 |

| 2 | 3 | 3 | Fitting of Controls to Ship | 6 |

| 3 | 4,5 | 1 | Main Transmission Fitting and Lift Strut | 7 |

| 3 | 4,5 | 2 | Tail Rotor shaft construction. TR gearbox. Tailrotor fitting. | 10 |

| 3 | 4,5 | 3 | Tailrotor balance and general information about design | 8 |

| 3 | 4,5 | 4 | Tailrotor gearbox mountings and alignment | 9 |

| 3 | 4,5 | 5 | Control rod fitting and swashplate alignment. | 15 |

| 4 | 9 | 1 | Turbine engine installation and control information | 12 |

| 4 | 9 | 2 | Governor construction and installation notes. | 13 |

| 4 | 9 | 3 | Turbine plumbing and fittings. Clutch Assembly. | 11 |

| 4 | 9 | 4 | Motor mount fitting and alignment | 14 |

| 5 | 6,7 | 1 | Rotor head fitting. | 16 |

| 5 | 6,7 | 2 | Rotor Blade Doubler Bonding | 17 |

| 5 | 6,7 | 3 | Rotor doubler continued and end caps. | 18 |

| 5 | ,67 | 4 | Rotor mounting and balancing. | 19 |

| 6 | 8 | 1 | Battery Box Mounting and general wiring information | 20 |

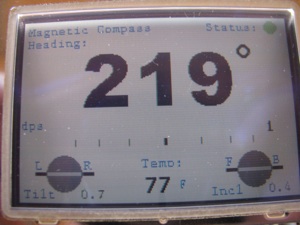

Finished Packaging Compass

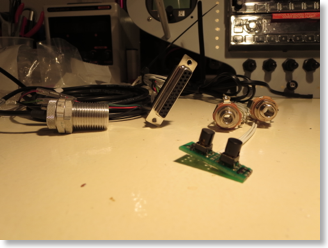

I finally finished packaging my homemade electronic compass. Small project box with some machined risers to house the thing.

That's just an experimenter board with the Arduino mounted and a 7805 linear power supply. Power draw is 0.18A at 12V, so about 2.2W. More than I expected, but not too bad overall.

Custom wiring harness connects to unit, power, sensor, and a DSUB9 in case I want to update the firmware with calibration data once its in the bird.

Sensor is shrink tubed to a little chunk of fiberglass. I will probably just tie wrap this to a fiberglass platform at the from of the pod's interior.

Wiring notes are here. I uses NotesPlus HD on the iPad to take hand notes in the shop. Better than paper and you get an instant electronic copy.

N-Number Reserved

Hooray! I got notice of my reserved N-Numbers from the FAA today. Though not difficult to get or an especially tricky milestone, it IS an indication of the project progressing.

I ordered some custom vinyl lettering from DIYLettering.com; Pre-cut green vinyl letters 3.5" tall. The font is "Impact", which looks very readable.

Panel Wiring

Instrument Cluster wiring harness is fabricated and installed. This is not especially hard, just tedious. I did not do a formal schematic since there is no real circuit design here, just connecting point A to point B. It was all tracked with spreadsheets. Once routed and the ends crimped, the bundles were lashed with spiral wrap nylon to tidy everything up. I drilled holes on the back of the GPS/COMM tray so everything could be hard-secured down. No wiggling wires. It is all very solid.

Of course once the wiring was done I had to make up a little test harness with power and switches for the XMIT and COMM flipflop as well as power and the sensors that NEED to be attached when powered up (the tach sensor).

Ahhh the money shot! Everything powered up and is functioning OK as far as I can tell. I rigged up antennas and could send and receive over the radio to my handheld and get GPS position data accurately.

One thing that became immediately apparent is that the COMM draws HUGE current (comparatively) when transmitting versus receiving. Nominally the panel was drawing just under 2 amps, but it spiked to about 4 amps, and quickly dropped to 3 amps when transmitting. Wow.

Hap Miller Bits

I ordered a bunch of bits and pieces from Hap Miller. Earlier I ordered and received his machined lift strut and it was of very good quality, so I wanted to see what else he has. Turs out a lot.

Here is the transmission oil cooler, clutch disk, and welded pitot tube. Nice!

Hap claims that the "T" on the oil return to the tank actually impeded the return oil flow, so he recommends second fitting to return the oil independently and will add one to your tank. He also has a nice machined cap with integral dipstick.

Lastly are the battery boxes. These mount just behind the transmission and accommodate a pair of Odyssey PC680 batteries. Nice aluminum welding work. It will be a shame to paint them and cover up those nice beads.

Fin Painting

The first “real” parts painted were the fins. This is Eastwood single-stage urethane. I first practiced on a couple sheets of aluminum I had in the shop, and good thing. There was a fair amount of fiddling with the gun and the first one was a mess.

Keeping the piece flat and getting the second and third coat relatively heavily allowed for a nice flow out. Very smooth. A little orange peel. Not much.

My one flaw is on the underside of the horizontal fin. The Fin slipped down the jig on which I had it and stuck to the piece of MDF I had underneath it. I will have to scuff this and repaint this side.

This is the vertical fin. Overall I am happy with the result. The only issue is that the Eastwood “Bright White” is not nearly as “bright” as I would have thought. It is slightly more grey than absolute white. I am getting used to it, though.

Now that the fin is painted I can select an N-Number and affix it to the fin. Progress.

Ground Plane Paint

For the structural parts I bought some enamel paint that matched the frame powder coating. This is the ground plane for the comm antenna.

Pre-Wiring

Instrument Fitting

Gauge holes trimmed up and gauges fitted. I decided to fit the large gauges behind the panel just to improve the symmetry and improve the look. The square gauge on the right is my homemade digital compass.

To flush mount the tach, I made this little plate to capture the gauge behind the panel. It’s really flat and parallel in spite of the camera distortion.

I am really digging having the mill with DROs. Made up a little sketch of the angles to mount the trays from the Garmin specs, measured and drilled and everything fit. The digital readouts make this operation a cinch. Also, the tolerances achievable are amazing.

Freehand, this would have required a bunch of fiddling and tweaking to get to fit. With the precision of the machine tools it basically falls together.

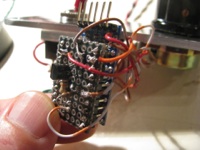

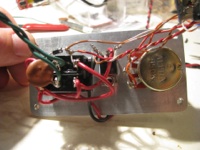

Mill DRO Design & Build

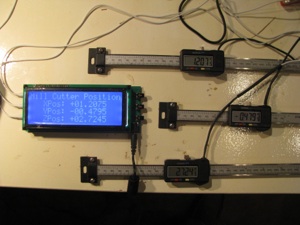

Clearly an accurate digital readout of the X, Y and Z-positions of the table and mill head will make jobs go much faster.

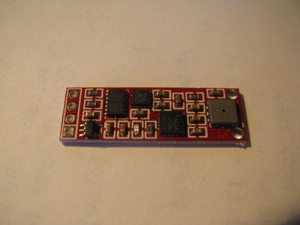

I purchased 2x12” and 1x8” digital caliper mechanisms off eBay for $24 for the 12” and $18 for the 8” respectively. I have read about various folks interfacing to those and hooked the interface signals up to a scope and observed and played around until I figured out exactly the protocol coming over the interface ports from the calipers.

For the ones I purchased the protocol seems slightly different than that measured by others. In my case the value output over the interface is simply a hex representation of the position in whatever units are selected (mm or in). One of the bits indicates the sign (it is not true twos complement), and another bit indicates the 0.0005” indication.

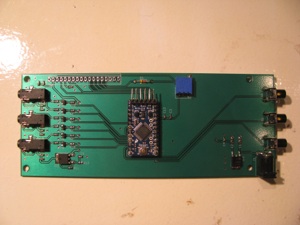

I whipped up a circuit to convert the voltage levels and wrote code to read the three values with an Arduino (that’s a ProMini in the center). I soldered the wires from 3 cellphone headsets (4-pin 3.5mm plugs with very, very fine flexible wires) to the caliper ports. The complete headsets were $0.99 each on eBay, which is cheaper than it would have been to buy connectors and cable and make my own. There’s $7 of buttons, connectors, passives, transistors, and regulators from Digikey rounding out the B.O.M.

The crowning piece is a large-character 20x4 character LCD display also bought on eBay for $22.

I layed out a circuit and had it fabricated through Sunstone.com using their “Value Proto” service, which is relatively cheap. It’s mounted here behind the LCD. There are buttons on the right for zeroing out the reading on each axis independently for positioning on a workpiece.

The Arduino is clearly running at capacity to handle the three calipers worth of data. Each caliper has a clock and data line. The clock triggers an interrupt, which causes me to sample the data line on the respective port. Two of the clocks trigger the ATMega’s native pin interrupt functions and the third (Z-axis) triggers a pin change interrupt (which is a bit slower). About every 20 seconds or so one of the readings may glitch and a weird reading is indicated for one loop, probably because of a sampling error caused by the fact that the interrupts are happening right on top of each other, causing me to sample one reading incorrectly. It is so infrequent that it will not affect usage of the DRO.

Uber Weenie Alert!:

Here are the technical details of my DRO circuitry and Arduino code for my setup. If you have questions feel free to email me as the above descriptions are pretty terse:

DRO_SupportBD_sch.pdf

DRO_SupportBD_brd.pdf

DRO_Rev3.ino

LCD_Support.ino

8/10/13 - DRO Mounting and Finishing of the Mill. I bought the FIgnoggle plans, and downloaded the free plans from the Little Machine Shop for mounting the DRO scales. Then I proceeded to ignore them both since they seemed overly complicated. They might make sense if you were trying to actually read the indicator on the scales themselves, but since I have my new big display, I found I could simplify the the mounting scheme to simple plates and spacers. The only tricky one was the 6degree wedge to vertically align the Y-axis mount with the base angle. No problem - I have a mill.

Y- Axis Mounting. The sliding part of the scale is mounted to the Y-axis carriage. An 0.040” plate is screwed into the caliper’s tapped holes, then 10-24 holes are drilled and tapped into the carriage (be careful - not to deep or you’ll hit the ways). There’s another 0.25” spacer behind those allen bolts, elevating the slider. The scale is fixed to the base using the supplied brackets and a wedge machined down from 0.25” plate. Just put an elongated slot in the wedge and you can slide it up or down until it is spaced properly.

X-Axis mounting. I didn’t want the scale on the front since it would interfere with the Y-handle and the gib lock. The only tricky part was that there was no way I could drill from the back and I didn’t want to remove the column. I used the pre-existing holes for the rubber boot and machined a plate to mate with those pre-existing holes and allow for the slider plate no the caliper to screw into it. The scale is simply mounted to the table on one end. Only one hole is needed and washers (which I have many of and various thicknesses) to fix the scale to the table. The display is fixed to the Y-axis carriage, the scale is mounted ot the X-table. I then mounted a fixed angle to the table to cover and shield the scale.

Z-Axis DRO Mount - I removed the existing visual scale (next to useless), as well as the existing spring support. This freed up a lot of room to mount the DRO scale.I just opened up and tapped on of the already existing holes on the column, and drilled two holes in the head casting for the slider. Again, an 0.040” plate on the caliper slider and a 0.25” spacer on the head casting. Simple. As before, be careful not to drill&tap too deep on the casting or you’ll hit the ways.

Other Mods - I purchased the Air Spring kit from Little Machine Shop. This provides two things; 1) A better spring, which is more linear and allows for greater travel of the head, and 2) a longer rack so that you can lower the head much closer to the table.

DONE DONE DONE! Now, a fully enhanced X2 class mini-mill. Extended travels on X, Y, and Z axes, a power feed, and DRO on all three axes. Nice to be completed and I learned a lot and practiced more machining technique.

Took the opportunity to scrub the shop from top to bottom and prep for the next project(s) now that this one is in the bag.

Mill Power Feed

I used it as an exercise in machining to build a frame to hold the gearbox and make an adapter plate to fit the mill.

For airplane parts it is common practice to drill parts in assembly. In this case however, I made sketches and machined all the parts to spec, being careful on all the measurements. Even though not necessary, I was able to hold tolerances to +/- 0.001” on all dimensions. Not bad for a noob. Everything fit together with very tight tolerance and no play anywhere. Satisfying.

To link the drill shaft to the X-axis lead screw, I machined a coupler with a tongue that mates to a slot already present in the lead screw, and then drilled a hole through the coupler and drill shaft.

The coupler is threaded for a couple of 4-40 allen screws. When they are backed out the coupler spins freely on the drill shaft in case I want to machine without the power feed engaged. A little cumbersome and it it becomes a pain I will fit a quick-release pin instead of the screws.

Speed Control for Power Feed. Being hooked up on the Arduino, I whipped up a little PWM program. It reads the voltage on a linear pot and adjusts a PWM signal output width. I just used a DPDT-Center Off switch to change direction and turn it off, so the Arduino’s job is simple. Just read a POT, adjust the PWM pulse width and drive a power FET (IRFZ44). A little Radio Shack Project box with the aluminum cover replaced with a 0.125” plate machined to accept the switch, POT, doubles as the heat sink for the FET as well. Works great.

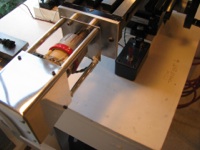

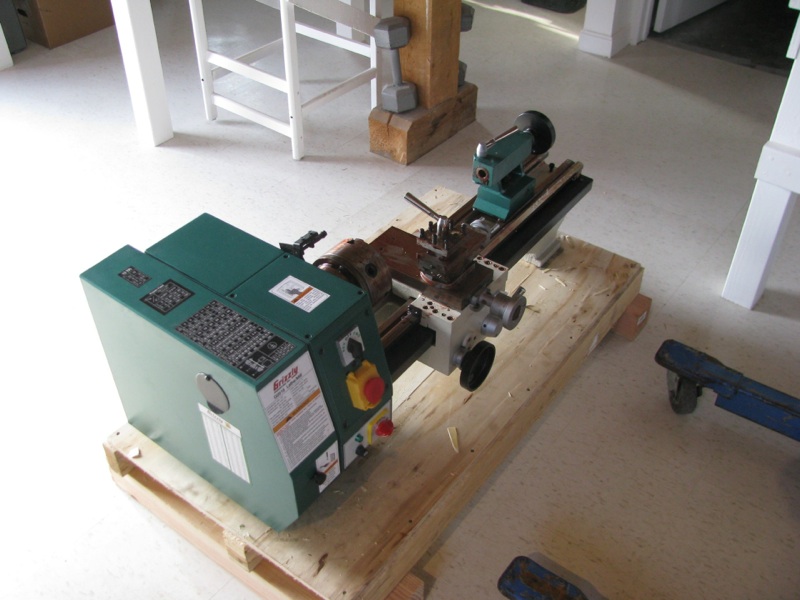

Milling Machine

About 3 years ago I invested in a Grizzly G0516 Lathe/Mill/Drill. The lathe is great. Very capable. The drill very precise. With patience you can drill very accurate holes. Milling left a lot to be desired. It took a lot of setup and then the machining was tough with the small mill table and relatively imprecise control using the lathe slide as the table movement control.

On paper it sounds great, but like many before, I have realized its limitations and really only used it for milling maybe 4 or 5 times seriously.

Little Machine Shop (.com) offers this milling table (shown here upside down). It is a little larger than a Sieg X2 table and the G0516 milling head bolts right to the back, effectively making a big-table X2 mill.

Step one is to fabricate a sturdy table made to fit in the only convenient spot left in my shop (too many projects). 4x4 legs, 2x6 table stringers, 3/4” ply and 3/4” mdf forming the top with 3 or 4 coats of urethane to seal it all up.

Everything is screwed and glued to keep it as stiff as possible. The surface is true within 0.1degree (I love my digital level).

As with the lathe, the first step is to take everything apart, clean off the shipping grease, and check all the surfaces. It felt pretty bad right out of the box - very sloppy movement - alternatively too tight and too loose with lots of side play.

That shipping grease turns to something like chewing gum and some of the sliding surfaces had paint on them. Don’t even think of using these Chinese machines right out of the box.

But as with the Grizzly, after a little work the motion cleans up, smooths out, and the tolerances can be snugged up substantially.

Virtually no play on the table movement once the gibs are adjusted. The motion is kind of stiff. After some use I may lap the ways and gibs to smooth it out and allow freer motion.

Complain as folks might about the Chinese machine tools, the value per dollar is amazing.

I don’t have any pictures of my tramming - my first time doing it with any precision. It took hours. I first made a tool I could chuck up in the mill that rigidly held my dial indicator 3-4 inches off centerline.

The Y error was about 9 mils at the start. This is the fore/aft “lean” of the mill column. To adjust it you unbolt the casting that holds the giant column mount stud, tilt it the appropriate direction and add shims to the appropriate side. Very thin shims. Doing the trig showed that I needed 2.5-3.5 mils of shim. My thinnest shim stock is 5 mill brass, so I ended up using aluminum foil. Lightly grease up one side (so it sticks) and layer it together. I needed a strip about 3 layers thick to get the Y tram. Since aluminum is not the strongest, I will have to check this periodically.

Since the column is designed to tilt left and right, it is just a matter of loosening the giant bolt and tilting/bumping the head until things are accurate, then snugging it down.

I ended up with about 0.5 mil Y tram error and just less in the X. I only have a dial indicator, so this is all probably within the error of the indicator, but sufficient for anything i will need it for.

Interestingly, the Jacob’s chuck had about 1.5mills of runout (since I was measuring stuff anyway). When I switch to a milling collet I will check the runout of that to see if its the chuck or the spindle head (I hope it’s the chuck).

The lathe denuded of the milling head. Whenever I needed the lathe it seemed I had t set up to drill and vice versa. This new arrangement should be much more efficient and I will be more inclined to use the mill for precision drilling instead of the old drill press.

Next up is to add my DRO indicators to the mill table. I’m going to make some chips first.

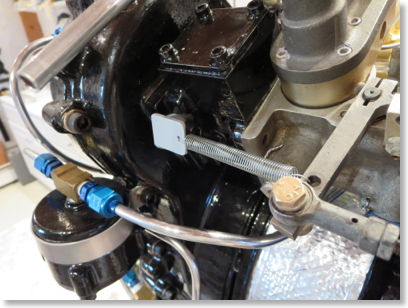

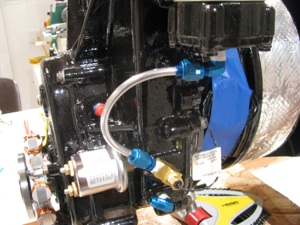

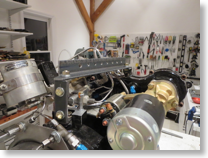

Turbine Plumbing Done

Completed plumbing of the engine oil system.

My tubing flare tool clamps just about an inch of tube, so you can’t begin a bend until then. I found it easier to offset the central Tee about an inch to be able to make the line from the top of the tank possible.

The top bracket is per BJ’s instructions. The lower one is bent for the actual offset needed so the bends were not too tight.

The money shot. Doing the tubing is a pleasant project. Try the run with wire first for test fitting, cut the tube, gently coax it into shape, polish, flare (don’t forget to add the fittings first - done that), and it all comes together. My son’s girlfriend said it looks like some 50’s science fiction movie prop with all the gadgets and tubes.

I don’t know if anyone else has the problems of a lot of scrap. This being a trial and error kind of thing I ended up with a lot of little pieces like this. I had to actually buy more Versatube from A.S.&S. to finish my job.

I got enough to make BJ’s “poor man’s oil cooler” should it be needed. I will try without first as I am in a chillier climate (especially this year). I’m not a fan of blocking the inlet airflow.

Oil Tank Fab

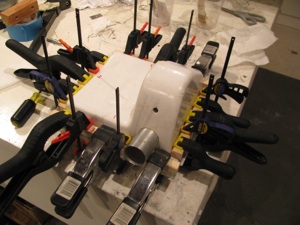

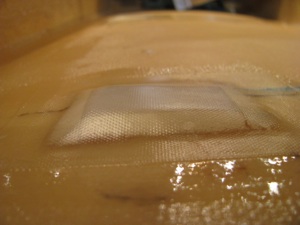

Fiberglassing together tank halves. Tidy up the insides (some stray bits of glass and cloth needed trimming, clean the surfaces with acetone, and bond the sides with a thick mixture of flox and resin.

Check for extrusion out each edge and clamp the hell out of it.

The tank mount brackets. You can see my many trial cardboard templates.

Thankfully I had an old ZVBox case that was 0.048” steel which I could use as a donor since there really isn’t enough steel strapping supplied to make the brackets, especially in the weird shapes you actually need, as opposed to the nice straight ones that BJ shows.

The videos show only two mounting points, top and bottom. I added a third using the one of the lower forward case bolts as the mount point. This takes it from something that could vibrate with some play to being very, very rigid to the engine.

There are a few points in the instructions like this, where it seems a very simple mod can add immensely to the strength/quality. I am sure I’m not the first to do this.

Finished tank with fittings mounted. I glassed the tank in the fall, but only just now finished mounting it this spring. My long winter of distractions, international travel, and business has ended and I plan on making very good progress on the helicopter again.

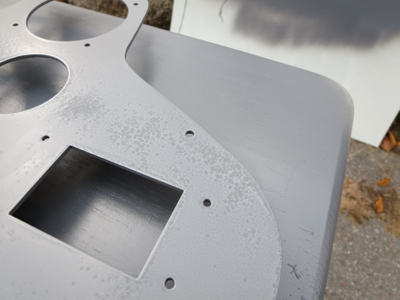

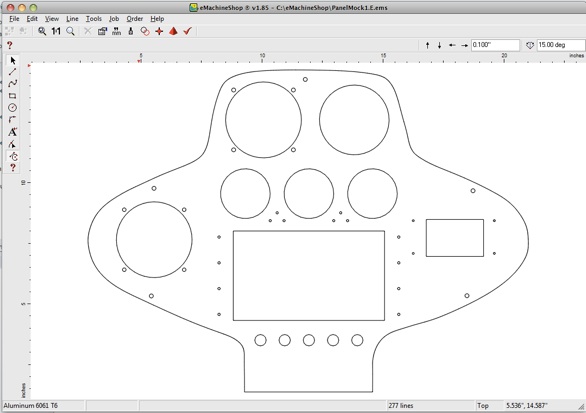

Panel Cut & Delivered

Panel Received. I discovered an online service called eMachineShop.com

This service will take a simple drawing and machine up a part for you. My method is to model the item in a “real” CAD system (in my case SpaceClaim), then import the drawing into their proprietary tool. You could do all your modeling in their tool, but it’s pretty primitive and yet another tool to learn. Select the material, and once it passes their design rule checks submit the part. A week later you get the item delivered. My panel cost me about $95 in 6061-T6 0.090” aluminum. I wanted some beef on the panel thickness to avoid having to add support structure for the planned avionics.

I took my aluminum “test fit” piece, traced it on graph paper, measured the points, and splined up the outline. Then I rough-modeled the instruments, shuffled them around and “cut” the holes. Everything is tight or slightly undersized so I can trim for a nice snug fit. As BJ says, it’s easier to remove metal than to add it back in.

And here is the finished item. It was returned in just over a week and fits perfectly. Some of the holes need trimming, but that was expected as I wanted a nice snug fit.

Here are the links to the rough DXF’s of my panel that I used to import into eMachineshop’s tools:

PanelMock1.A.dxf

LowerPanel.dxf

Compass Bug Killed!

Experimentally I found that my lab supply was the problem. The HMC5883L must go through some internal initialization at power up. I have a big honking lab DC power supply. Whenever I turn it off and on I get a relay click and a big hum - must be charging some caps or something. Anyway, when that occurs the compass chip must latch onto some stray field being put out by the supply which screws up its internal power-up calibration routine. Certain relationships and distances between the compass and the supply proved to be worse than others.

Using a different supply, or just a separate switch from the lab supply’s switch got rid of this behavior. Nice to have it understood/killed. My experience is that if you have a bug on the bench, even a very rare one, it will occur in the field - probably at the worst possible moment.

Electronic Compass

Every aircraft seems to have one of these, so I just assumed I should get one as well, so bought one from Wentworth on eBay for about $200.

It’s awful. Sticky motion and inaccurate (+/- 5 to 10 degrees). Now this one is used, and does not work as well as the one in my plane, but - damn - there has to be a better way to tell direction than sticking one off these butt -ugly devices on the top of the instrument pod.

Looking around the web revealed these little gems. This is basically an inertial navigation system on a little 1.5cm x4cm card.

Onboard there is a compass chip, a 3-axis accelerometer, a 3-axis rate gyro, and a barometer that tells temperature as well. All this for <$20.

Seems like one should be able to build a compass out of this pretty easily.

I took the opportunity to learn about the Arduino. Neat little micro - fairly self-contained with a well-developed open-source IDE. That‘s a sunlight readable LCD from EARTHLCD.

The display is driven by a serial line from the Arduino and the IMU module is interfaced via I2C. All-in-all some very simple wiring to get the whole mess working. Of course this will all get packaged up cleanly before installation for real.

The test jig. The rose is calibrated with a fluid compass to point North. The IMU is just taped to a block of wood. It’ll be mounted up in the nose of the instrument cluster pod.

I learned a lot about the earth’s magnetic field and compasses. I did not realize that the primary magnetic force vector points 70 degrees downward at my position on the planet.

What that means is that the compass works well if level, but is WAY off if tilted by even a degree or two. The solution is to use Z-axis of the magnetic field reading and the accelerometer to detect tilt. Then do the 3-D vector trigonometry to correct and compensate for the tilt.

All of this is a lot of math and was a good challenge. It’s been years since I did matrix operations and lots and lots of trig.

In the center there is a turn rate bar that varies in proportion to the rate of angular turn. Just like in a commercial gyro, the 3dps reading is a half scale bar. The bar deflection is proportional to the rate of turn and the displacement scale is exponential. The tilt readings are displayed since I had to compute them for the compass anyway. I calibrated the tilt against my $200 digital level and it is just as accurate.

For the uber-weenies out there, the code is attached. I make no license or warrantee that this will work for you. It works for me and that’s all I care about right now.

Air_Instrument5.ino Main program with primary execution loop

ADXL_Support.ino Support routines needed for accelerometer device

AI_Support.ino General purpose routines and conversions

AI_Types.h Data type definitions for passing vectors around

BMP085_Support.ino Routines for handling the barometric and temp sensor

Compass_Support.ino Routines for initializing, calibrating & reading the Compass Device

EZLCD_Support.ino Display device routines and drawing methods

Gyro_Support.ino Routines for driving the rate gyro device

I am extra-happy with the tilt compensation. You can now tilt the device (and ultimately the helicopter) up to about 70 degrees off level in any direction and the magnetic heading is still accurate. There is NO mechanical compass I know of that has that sort of performance envelope. Along the way I learned a ton. I plan to use that knowledge to build an airspeed indicator accurate to 5mph or less.

Beacon Strobe

LED technology has made leaps and bounds in recents years. I decided to build my own strobes based on some new 900 Lumen CRE LEDs. That’s 900 lumens each. My old-fashioned living-room flood light bulbs are each 800 lumens at 90watts, just to put that in perspective. According to the spec sheet you can get almost twice that light per device if it is not continuous duty by overdriving the current.

So six of these LEDs with a peak of 1800 lumens each gets us about 10,000 lumens. The trick is handling the current. At 4amps per device that’s 24 amps. You certainly don’t want to switch that on and off directly from the battery. The current loop in the ship’s wiring would induce its own set of problems.

So to deal with that I developed a little circuit that charges up a capacitor bank, discharges through the LEDs then charges up again. The sequence is a 25millisecond flash, pause 100 milliseconds, another 25 millisecond flash, then pause 1.5 seconds, repeat forever. The caps charge during that 1.5second delay and therefore the average current to the whole strobe unit is 0.3A at 12V and should be very easy on the rest of the ship’s systems.

Best of all, the thing weighs next to nothing. I haven’t measured, but it can’t be more than a couple of ounces.

Here’s the circuit. Ignore the two capacitors dangling in the breeze. They are bulk and decoupling for the ATTiny85 microcontroller that controls the sequence. I forgot to order SMT caps from Digikey and will replace those before buttoning it up.

For those interested the schematic can be seen at Strobe_A.pdf. If you do something like this, pay attention to the ripple current rating of the capacitors. Layout is Strobe_A_top.pdf.

The PCB was sized to fit in a polycarbonate sphere bought at a craft store. The shell is designed to be used as a homemade christmas ornament.

I used Sunstone circuits “Value Proto” service for my PCB. This is a very cheap PCB fab process that uses unused panel space on other designs going through to keep your individual cost down. The down side is that the lead time can be long since they have to wait for a design with spare panel space - but hey, it’s very, very cheap.

If you do something like this, bear in mind that if the lights were left ON continuously (not blinking) it would heat up quickly and destroy itself. This circuit only works if the duty cycle (lights on period) is very, very low. I have left it running for days blinking along with no problems and cool to the touch, with flash pulses that are retina-melting. If you look at it directly by mistake you will see spots for an hour.

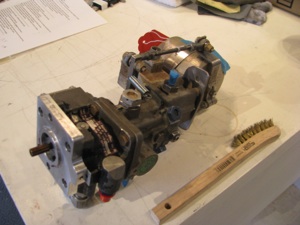

Turbine Prep

Various plumbing fittings, safety wiring, and painting of the oil filter housing.

My first oil line. I think I may have “overflared” the ends as a little ridge extruded out between the flare clamp dies which prevents the retainer ring from seating fully. This one is coming back. I practiced on a couple, but probably should have intentionally under and over flared to get a feel for what that looks like, Again, my second helicopter will be perfect.

Takes about 3 minutes to polish the line and makes a huge improvement in appearance.

Adding more lines. Engine is tilted up for better access to lower lines.

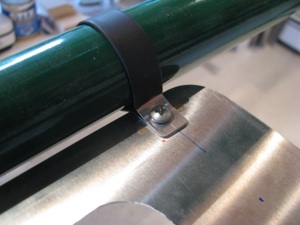

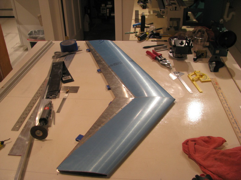

Drilling and Aligning Fins

To get the horizontal fin at the correct 5° angle, and to keep the relationship of the vertical fin reasonable and the position of the rear mounting hole centered in the doublers (don’t worry, it would make sense if you were building one), I found things to work better if I placed a 0.125” spacer under the front vertical fin mount. This also allowed for the milling of a tilt to account for angular mismatch between the fin and the frame mount. Quick job on the Grizzly.

When I first started making these tubes I thought I would simply use my fabricated tubes as templates and then go have a welder make “real” tubes with a welded endplate, but I must say that I am actually pretty pleased with the results. The double MAP torch trick seems to work as Home Depot MAP torches do not seem to burn hot or concentrated enough to thoroughly melt the tube, but the flame temp (3600 degrees) is well above the annealing temp (1590 degrees) of 4130 steel.

I may redo this one lower tube as the distance between the bend and the bolt seems a little long on the lower end. It is curious how things look worse in the digital photos than in reality. I guess this is good - like having a critical eye looking over your shoulder.

The finished (almost) fin mounting job. I just need to redo the single lower tube, final rivet the central fin doublers, drill the horizontal fin to its mounting stub tube and fashion a bracket at the rear of the horizontal for added support to the vertical. One evening.

Of course during flight checkout all these may have to be boogered around a bit, but for now I am pleased that they are spot-on the planned dimensions and angles.

Ground Plane Mounting

Fin Brace Tubes

I got out my torch and bent the tubes that are to support and align the tailfeathers. As with most operations that are new to me, the first one came out great, then the second two were sloppy I need a better device for squeezing and bending the heated tube that is a little more precise. I am going to do some experiments to see how strong the heated and bent tubes are as that is a questionable procedure in my mind. I am heating the tube with a pair of MAP gas torches which gets the tubes bright orange, but not cherry red. Good thing I bought an extra 3 feet of tubing from A.S.

I ended up grinding some generous curves on the outside of a couple of chunks of aluminum angle to cover the vice jaws, so that when I squeezed, the hot tubing it would have a gentle bend instead of a sharp break at the end of the angle.

Every time the tube is heated and squeezed the aluminum picks up some scale from the steel that has to be scraped off since it’s hot enough to braze the scale to the aluminum surface and stick.

Once the hot tube touches the jaws you have about 2 seconds to complete the bend before the heat is wicked away and the tube re-hardens.

Once the squeeze and the angle look good, reheat and get the whole bend bright orange to re-anneal and let it cool very slowly. I played around with more rapid cooling on test pieces and it makes a huge difference. I had one piece so hard that drill bits could not get any bite at all and just burned.

Ground Plane

After having read Juan Rivera’s web site I decided that I would include a ground plane to improve the performance of the VHF communications antenna. The comm frequency range is 118 to 136 MHz. Therefore the 1/4 wavelength range is 21 to 25 inches. The sheet is 28 inches long. The longest diagonal opening is about 6.5 inches. No hole should be more than 1/10 wavelength (8.5 to 10 inches) so this should work well.

Cutting the sheet was a royal pain, but I didn’t want to just rivet strips together as the impedance across the joints would have adversely affected the RF performance of the ground plane. Drawing for the ground plane sheet is GroundPlane_B_072012.pdf.

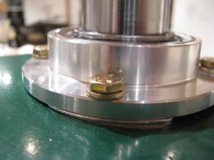

Machining Shaft Dogs

Because of the curved taper from the shaft collar to the dog face, the washer/bolt interferes with the curve.

I could have filed an angle on the washers, but that seemed a little inelegant, and I DO have this wonderful mill.

Like all the machining I have done, clamping aligning and measuring is 90% of the time and the actual metal cutting takes about 12 seconds.

I was careful to not take off very much. This is a jumbo-thick part, so I am sure it is plenty strong, but I still did not want to cut full width flats as that would have eaten quite a bit more metal.

Bracket Repair

Initial Panel Fabrication

Fitting the lower instrument panel. The initial fitup is with a sacrificial aluminum sheet. Once everything is placed I will use it as a template to transfer the holes to the actual sheet to be used.

The hole is cut so I can get my hand in there and place a bracket on the pan to affix the panel on the lower edge, which should definitely strengthen things up. Screwing it in will be a pain since the cyclic riser is in the way, but not too bad with a 90 degree phillips.

Initial cutout of the upper. This again is a sacrificial piece of aluminum. I wanted to see where I stand before messing around with the shape.

Obviously the upper instrument pod is flatter and narrower than the specified dimensions by a lot.

The drawing sheet shows an 18 3/8” width at the widest point. I am seeing almost an inch wider and and inch and a half “shorter” from the bottom to the top. I am going to have to shim the side lobes to get more vertical space and hopefully narrow it up some.

I’ll use some blue foam blocks to push the upper section up, but probably won’t get to the specified dimensions without really distorting the pod from it’s relaxed state, which I don’t want to do. The primary requirement is that the side lobes be large enough for a 3-1/8” instrument. Once that is close enough for me I will glass in the foam spacer blocks.

Engine Stand

Received Fixed Bearing

After more than a month I received my rebuilt tail rotor slider bearing from Eagle. Smooth. I can now finish up the tail rotor assembly.

POR15 Engine Painting

The engine has been painted with POR-15 gloss black. This stuff is really shiny and flows out oh so slowly.

The most time-consuming part was masking all the heads of the allen head bolts. That took forever and then was painful to remove as the POR really grabbed the tape.

I had to touch it up with an artists brush after removing the masking tape. but it’s finally done.

The POR-15 flows out very slowly. I can’t believe this is a brushed-on finish.

Now this is a rough casting, so I was not expecting a show quality finish, and it isn’t, but overall I a pleased with the outcome. The paint flowed out evenly and the brush marks disappeared.

It appears to be a thick, tough finish.

Cracked Manifold Bracket

One flaw I noticed was that the bracket on which the fuel distribution manifold is mounted is cracked. You can just see the crack in the bent angle of the bracket. I will have to have this rewelded before the engine goes in. It really wasn’t evident until the manifold was removed, so I can’t really get down on Eagle for this. I will truck the engine over to my airplane mechanics to be repaired before starting re-assembly.

Paint Planning

Now maybe because I’ve been staring at it in the raw gelcoat for so long, the white has kind of grown on me. Green frame, white fins and cabin with a flat black interior (low reflections). That’s the working direction. Basic, not gaudy. Works with the green and won’t offend anyone, nor will it impress with any great inspiration or creativity either. I should be able to pull this off myself since there are no swoopy transitions and multi-color blends. I may add some trim colors, but only later and maybe with vinyl graphics.

Does the table at the top look impressive? It should. That’s $450 worth of painting chemicals. I am quite sure I bought way too much flat black and not enough white, but we’ll see. Eastwood had the stuff to me within 4 days and I didn’t pay for any expedites (every can was dented, but not breached).

Instrument Panel Planning & Fitting

Instruments planned for the upper pod:

TOP ROW: Airspeed Indicator, Rotor RPM

MIDDLE ROW: Altitude, temp gauges, Flow Level/Flow, Vertical Speed

BOTTOM: GPS/COMM , Transponder, Compass

Lower Section: Switches, Engine RPM, Breakers

All but one of these are provided with the kit; Voltage, Transmission Temp, Hour Meter, Flow Flow (I supplied), Tachometer, Turbine Exhaust Temp, Engine Tach, and Oil Temp and Pressure.

Leftover from my RV8A project is a Garmin GNC300XL GPS/COMM and a GTX327 transponder.

Left to purchase is an AS indicator, Altimeter, and VSI.

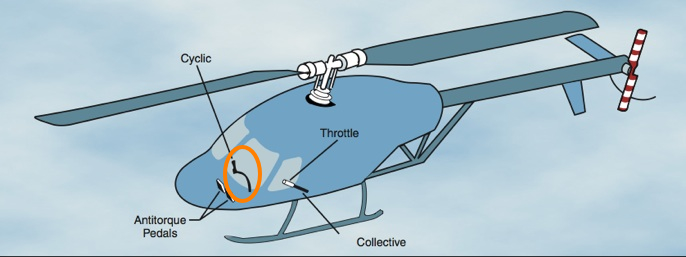

Checking the instrument pod positioning. And... making helicopter noises. One of those FAA “builder” pictures.