Panel Cut & Delivered

04/01/13 17:23 Filed in: All

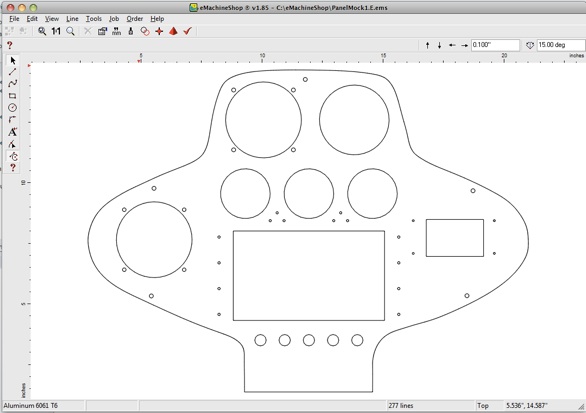

Panel Received. I discovered an online service called eMachineShop.com

This service will take a simple drawing and machine up a part for you. My method is to model the item in a “real” CAD system (in my case SpaceClaim), then import the drawing into their proprietary tool. You could do all your modeling in their tool, but it’s pretty primitive and yet another tool to learn. Select the material, and once it passes their design rule checks submit the part. A week later you get the item delivered. My panel cost me about $95 in 6061-T6 0.090” aluminum. I wanted some beef on the panel thickness to avoid having to add support structure for the planned avionics.

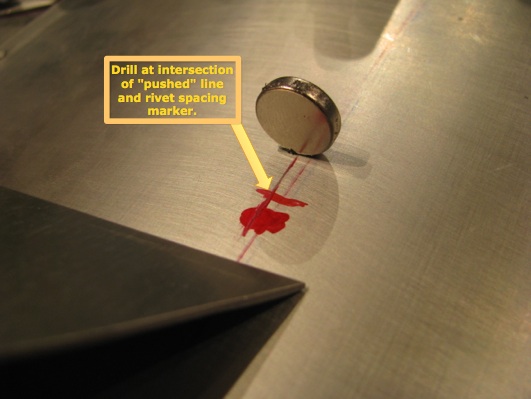

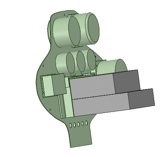

I took my aluminum “test fit” piece, traced it on graph paper, measured the points, and splined up the outline. Then I rough-modeled the instruments, shuffled them around and “cut” the holes. Everything is tight or slightly undersized so I can trim for a nice snug fit. As BJ says, it’s easier to remove metal than to add it back in.

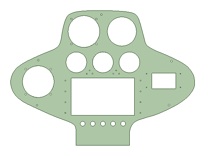

And here is the finished item. It was returned in just over a week and fits perfectly. Some of the holes need trimming, but that was expected as I wanted a nice snug fit.

Here are the links to the rough DXF’s of my panel that I used to import into eMachineshop’s tools:

PanelMock1.A.dxf

LowerPanel.dxf