Turbine Plumbing Done

05/27/13 14:29 Filed in: All

Completed plumbing of the engine oil system.

My tubing flare tool clamps just about an inch of tube, so you can’t begin a bend until then. I found it easier to offset the central Tee about an inch to be able to make the line from the top of the tank possible.

The top bracket is per BJ’s instructions. The lower one is bent for the actual offset needed so the bends were not too tight.

The money shot. Doing the tubing is a pleasant project. Try the run with wire first for test fitting, cut the tube, gently coax it into shape, polish, flare (don’t forget to add the fittings first - done that), and it all comes together. My son’s girlfriend said it looks like some 50’s science fiction movie prop with all the gadgets and tubes.

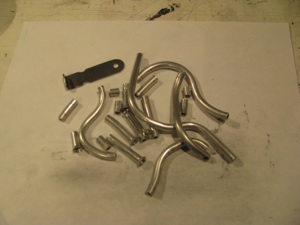

I don’t know if anyone else has the problems of a lot of scrap. This being a trial and error kind of thing I ended up with a lot of little pieces like this. I had to actually buy more Versatube from A.S.&S. to finish my job.

I got enough to make BJ’s “poor man’s oil cooler” should it be needed. I will try without first as I am in a chillier climate (especially this year). I’m not a fan of blocking the inlet airflow.